Electronics Manufacturing

Check out our free Buyer’s Guide and learn how low or fluctuating humidity can negatively affect electronic manufacturing facilities.

Ensure consistent yields, minimize ESD risk, and improve product reliability with DriSteem humidification systems—engineered specifically for electronics manufacturing environments like cleanrooms, PCB lines, and semiconductor fabs. Our solutions maintain precise RH conditions while reducing energy costs through efficient, scalable technology.

Why Humidity Control Matters for Electronics Manufacturing

Humidity isn’t just a comfort issue in electronics facilities—it’s a critical control point. Without consistent RH levels:

- Electrostatic discharge (ESD) events become more frequent

- Soldering defects like voids and delamination arise

- Moisture-sensitive components suffer corrosion and degradation

- Cleanroom conditions become unstable, impacting tool performance

Maintaining RH between 40–60% is widely recognized as the safe zone for balancing risk, reliability, and regulatory compliance. Read our article in EE Times: “Humidity Control Best Practices for Electronics Manufacturing” to learn more.

Products Built for Electronics Manufacturing

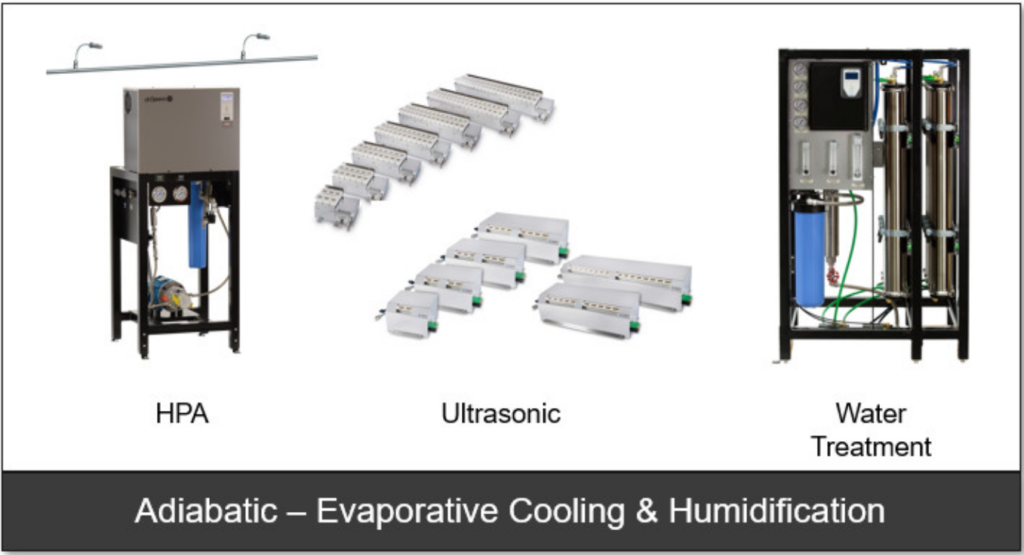

Adiabatic Solutions by DriSteem

Ideal for: Energy-conscious, high-latent-heat facilities and open areas (e.g., aerospace, PCB lines).

- Adiatec® High-Pressure (HPA) System: High-pressure atomizer that delivers precise humidity control and free cooling, ideal for large electronics manufacturing spaces

- Adiatec® Ultrasonic System: Precise, localized humidity control with ultra-low energy use; quiet for smaller spaces

- DriSteem Water Treatment: Supports humidification system longevity and air quality

Isothermal Solutions by DriSteem

Best for: Fabs requiring precise RH tolerance, audit-ready performance, or steam integration.

- RTS® Humidifier: Powerful, scalable, and reliable isothermal steam humidifier that delivers clean, consistent humidity control, ideal for applications where precise RH is required without additional cooling.

- Ultra-sorb® Steam Dispersion Panels: Designed for rapid, uniform steam dispersion into air handling systems, providing precise and consistent humidity control with minimal condensate

- DriSteem SDU: Space distribution unit for point-of-use control

Key Benefits by Application

1. Prevent Electrostatic Discharge (ESD)

Problem: Low humidity increases ESD risk, damaging semiconductors and PCB components, reducing yields, and disrupting operations.

Solution: Maintain RH between 40–60% to reduce surface charge buildup.

Supports and enhances:

- Ionization systems

- Personal grounding protocols

- ESD-safe packaging

- Cleanroom SOPs

2. Avoid Process Defects and Yield Loss

Problem: Humidity swings during soldering or curing lead to:

- Solder voids and poor wetting

- Delamination

- IC popcorn failures

- CAF formation from excess moisture absorption

Solution: Humidification ensures consistency across soldering, reflow, and curing steps, supporting IPC/J-STD-033B.1 standards.

3. Improve Equipment and Material Reliability

Problem: RH fluctuations cause corrosion of exposed metals, oxidation of solderable surfaces, and reduce the shelf life of moisture-sensitive components.

Solution: Integrated humidity control protects components from rework, scrap, or field failures by pairing with moisture barrier storage and JEDEC-tracked environments.

4. Stabilize Cleanroom Conditions

Problem: Tool-to-tool RH mismatches cause process drift, AMC formation, and yield variance in critical tool zones.

Solution: Localized humidity systems stabilize mini-environments inside FOUP docks, etch chambers, litho tracks, and reflow ovens.

5. Reduce HVAC Energy Costs

Problem: Cleanroom HVAC systems are energy-intensive. In fact, 27% of cleanroom energy goes to chillers alone.

Solution: Adiabatic systems (like pressurized water atomizers) reduce energy load by leveraging evaporative cooling. Studies show:

- 8–23% lower total energy use

- Lower HVAC burden via return-duct installation

Ready to Take Control of Humidity?

Partner with DriSteem to engineer a humidity solution that meets your facility’s technical requirements, energy targets, and compliance standards. Contact your local DriSteem humidity control expert to learn more about humidity control for electronic manufacturing facilities.

Connect with a humidity control expert

Already using humidity control to protect electronic manufacturing facilities?

For optimal performance and maximum efficiency, existing humidification systems should be inspected to determine if any replacement parts are required, if additional maintenance is necessary, and whether a software update is available. Contact your local DriSteem representative to learn more.